How does the production of a ring work?

On our website you will discover dozens of beautiful wedding rings. There are different designs to choose from, in all possible styles.

But have you ever thought about the production process? Few people know how a ring is made.

Well, today we'll give you a hint. We'll take you into our workshop and explain step by step how a ring is made.

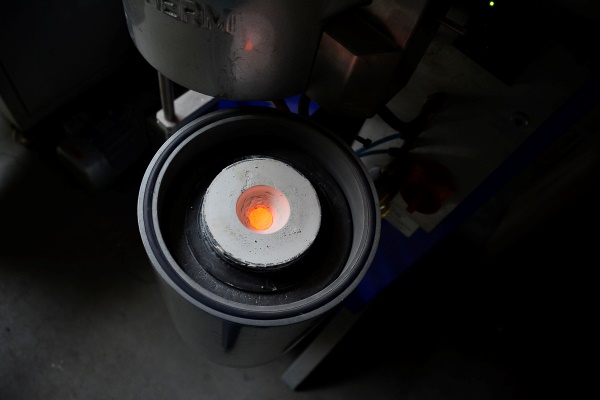

Step 1: melting silver

The first step of the production process consists of melting pieces of silver. We need this material for the creation of a prototype. The heating is done by means of a gas burner. It takes a while for the silver to melt, because this metal has a melting point of about 960 °C.

Step 2: rolling

We pour the molten silver into a mould. Once this has cooled down, we pass the silver rod through a series of rollers. This process makes the metal thinner. Eventually we get a long, narrow strip.

Step 3: design

In the third step we shape the ring. This is manual craftsmanship. The silver is heated to attach the ends to each other, so that everything forms one piece. Afterwards we add some decorations to give the ring its characteristic design. Experience is crucial in this step of the production process.

Step 4: Mould making

In the next step of the production of a ring we make a mould. This mould consists of rubber. Later wax will be poured into it.

Step 5: Melting and casting gold

Next we go to the foundry. Here we melt the gold. This requires a lot of heat, because gold has a melting point of no less than 1,064 °C. So the necessary safety precautions are taken. After the casting the ring has to cool down for a while.

Step 6: finishing

The final step consists of a finishing phase. We ensure that the finished ring meets our high quality standards. For some models we also add diamonds or other gemstones as a finishing touch.